Many of Pascal’s quick change mold clamps and other products are time savers that can help you to reduce downtime and increase productivity and safety.

Here is an example: If you can save at least 15 minutes on each mold change and you have 4 mold changes per day, that equals 22 hours a month. You would save 11 days per year! There is often much more than 15 minutes savings per quick changeover, so a quick mold change system could potentially gain you even more time!

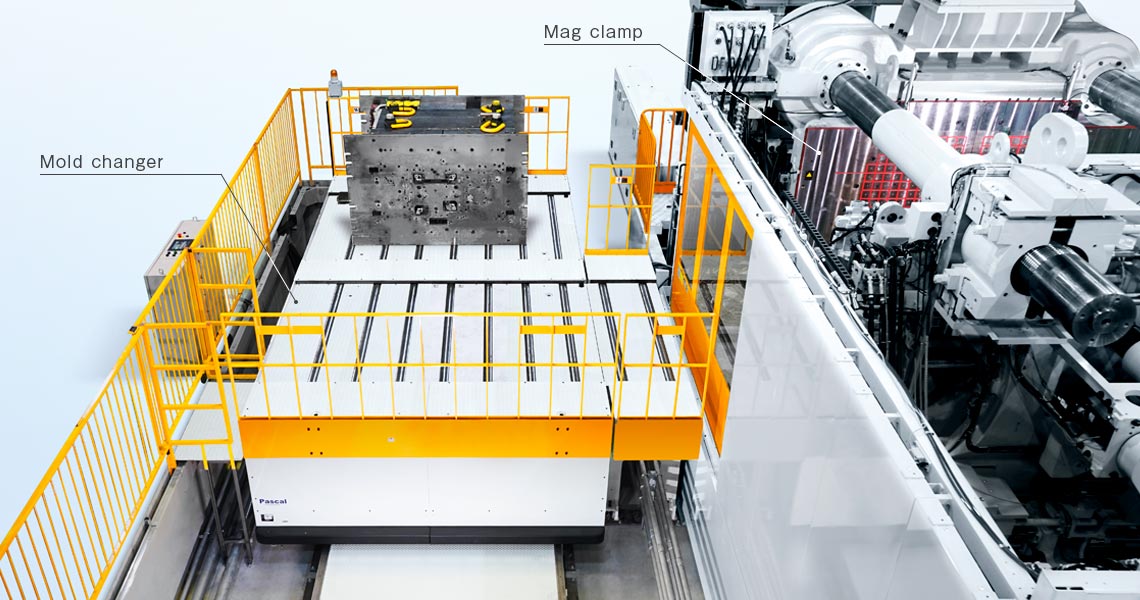

There are many types of molding machine and mold tooling options for quick changeover. Pascal can evaluate your situation and requirements and develop the optimal automatic quick mold change system for your process and operation, using combinations of the mold changeover products listed below.

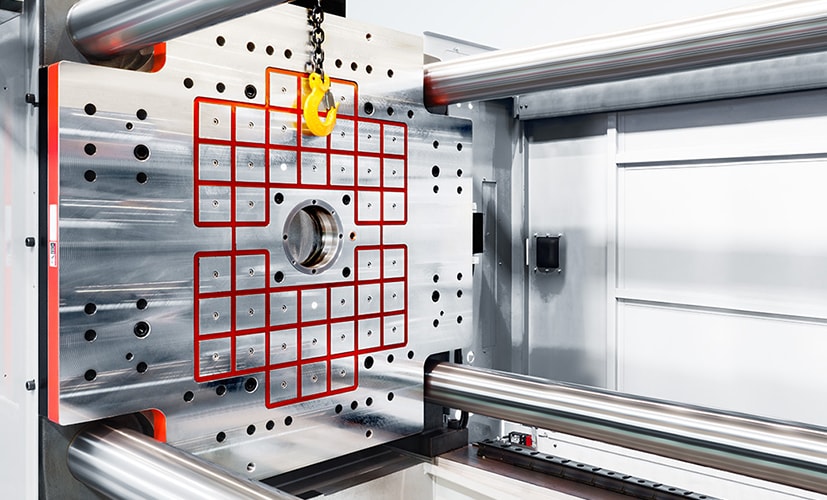

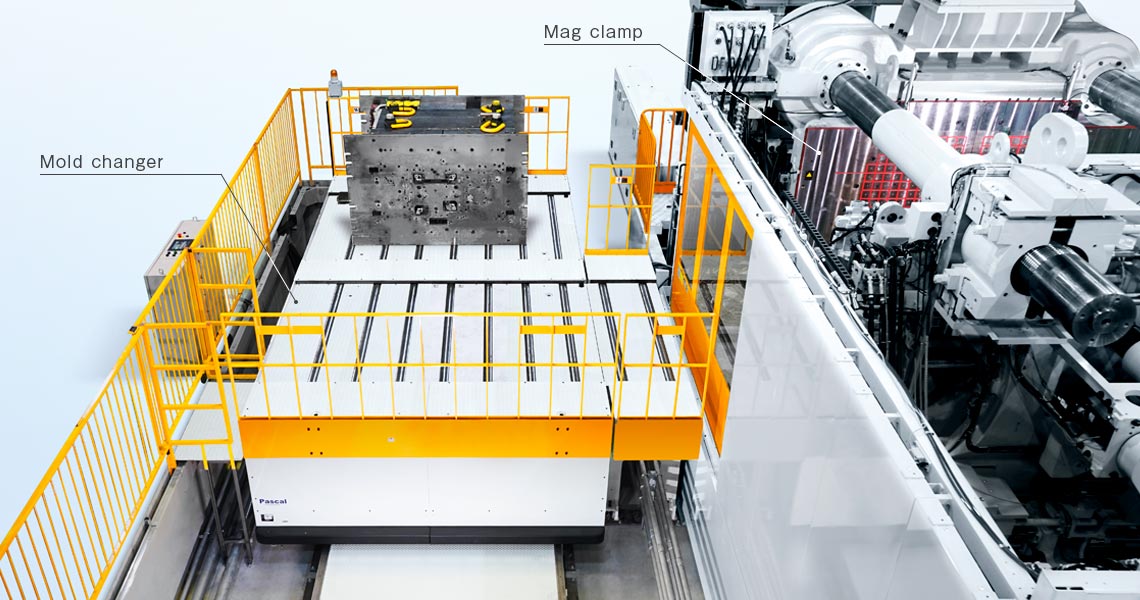

Magnetic Platen: A magnetic platen or magnetic clamp does not require any tools, and it clamps and unclamps at the push of a button in just 0.5-4.5 seconds.

Hydraulic/Air Clamps: A wide variety of mold clamps and die clamps are available including T-slot slidable types, long stroke types, t-slot less types, bolted types, and other automatic clamps with sensors in a variety of sizes and options.

Control system: This air-driven unit controls the hydraulic and air clamps. Most of our control systems are solenoid operated, with options ranging from small to large injection molding machines. An electric motor drive control for large IMMS is also available, along with non-leak valve units.

Mold/Die Changer: The next mold can be loaded onto a mold changer while the IMM is in operation, stopping operation only for a quick swap of the molds.

Automatic Coupler: An automatic coupler can connect multiple ports for hydraulics, water, and air all at once, saving time and guesswork.

Multi Coupler: The multi coupler is similar to the automatic coupler, except it is a manual option that can come with or without a check valve. It has ports for water, hydraulics, and air ranging from 4-12 ports.

Ejector Rods: Pascal’s magnetic Easy Ejector rods are lightweight and require no tools. For a 100 ton injection molding machine the time spent swapping ejector rods went from 1 minute and 6 seconds down to just 8 seconds!

Rotator: A mold rotator or mold flipper can safely rotate large molds and dies in seconds, and no one has to guide the mold with a crane.

Locating & Positioning Devices

Octagonal locate ring: Pascal’s highly rigid and durable locate ring provides high accuracy mold positioning for insert and hoop molding. It can help to improve mold set up time by connecting in seconds, and it eliminates the need to reteach robots. The locate ring is designed with 8 faces provide easy centering. Many options are available for vertical loading injection molding machines from 50 tons and upward.

Die Stopper: This is available as an alternative to the die fall protection hook. It prevents the die from falling due to the misplacement and nozzle touch of the ejector and ensures quick clamping.